Deepwater Oil Recovery

The task was to remove oil from the wreck of the tanker ‘Kyung Shin’. This tanker went down many years ago off the country’s south east coast, in a water depth approaching 100 m.

Remove oil from 100 m water depth

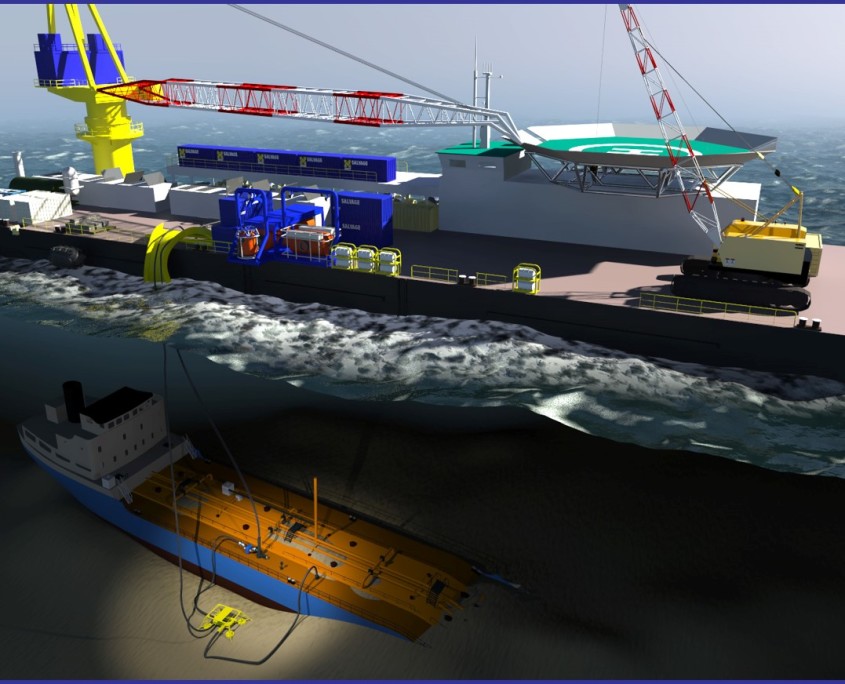

The task was to remove oil from the wreck of the tanker ‘Kyung Shin’. This tanker went down many years ago off the country’s south east coast, in a water depth approaching 100 m. The crane barge ‘Smit Borneo’ was mobilised as the surface platform for this operation. The spread included a saturation spread and team, hot-tap equipment (for pumping from the submerged tanks) and a newly designed tank heating system. The operation recovered about 500 tonnes of HFO from the vessel’s tanks.

Tanker sank in 1988

The Korean fuel oil tanker ‘Kyung Shin’ sank in 1988. She was lost in the Sea of Japan, close to the South Korean port of Pohang. Given the depth of the wreck, it was decided not to remove the vessel. However, action was taken to reduce the environmental threat.

Persistent oil seepage

Nevertheless, over the years there has been persistent oil seepage from this wreck. The leakage was small, but KOEM carried out a risk analysis, taking into account the possibility of a larger scale release of oil from the ‘Kyung Shin’. It was at this point that the Korean authorities approached SMIT Salvage, an organisation with a solid track record for successful oil recovery.

Wreck inspection

During 2010 KOEM contracted SMIT Salvage for the task of carrying out a wreck inspection. In response, the crane barge ‘Smit Borneo’ and the multipurpose tug ‘Smit Angola’ were mobilised. The spread included a saturation diving system and other specialised equipment, to take account of the depth at which the inspection would be performed.

Detailed pollutant recovery plan

The diving team surveyed the wreck, measured the volumes remaining in each tank and took samples. Several compartments were found to contain various grades of fuel oil. This information was then used to develop a detailed pollutantrecovery plan. The plan was accepted and SMIT Salvage was then awarded a contract to remove the oil during the summer of 2011.Specialised equipment‘Smit Borneo’ was prepared for this task. The vessel was fitted out with equipment from SMIT’s warehouse in Rotterdam, including a hot-tap system, boilers, heat-exchangers and special pumps and hoses. Meanwhile, the SMIT Subsea SAT-3 saturation diving system was mobilisedfrom Dubai.Success factor the right temperature‘Smit Borneo’ and 80 tbp tug ‘Union Boxer’, departed Singapore in early June for this oil recovery, which proved to be something of a technical tour de force. One crucial success factor involved producing the correct temperatures for optimum pumping of the various fuel oil grades. This was achieved by the use of warm water heating, to reach the required temperature for pumping. Spiral heat exchangers were inserted into each tank, by means of the hot-tap system. When oil reached the surface, it was passed through an oil-water separator. During the operation, completed on July 10, a total of 12 tanks were emptied.